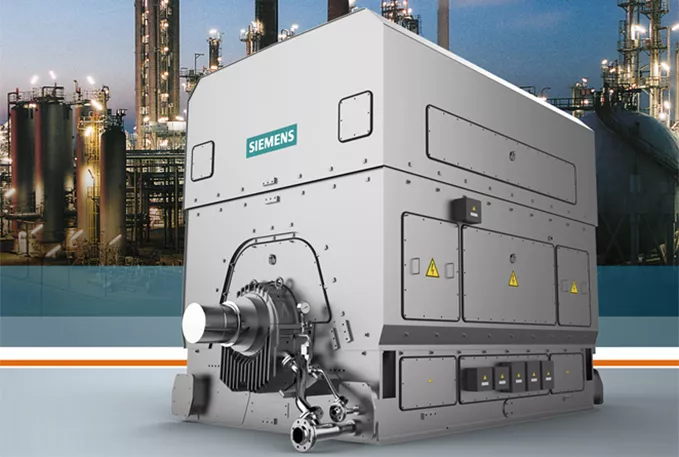

Hazardous area solutions for large electric motors & generators

Expo Technologies is the world leader in protection systems for large electric motors and generators. With the largest installed base of any manufacturer, we are a trusted partner to most of the world’s leading manufacturers.

In line with all other electrical equipment used in hazardous areas, electric motors and generators require certification using a recognised protection method.

Download our brochure to find out more.

Read More

Flameproof/Explosion-proof (Ex d) construction is often used for small machines, but this is impractical and expensive to implement on large machines.

Through design, large machines can have reduced risks of sparking or excessive temperatures. In these cases, certification as Increased Safety (Ex e) or Non-Sparking (Ex nA) is possible. All Ex e and Ex nA machines are required to be further assessed for possible air-gap sparking and may require additional measures, such as pre-start ventilation with air before start-up.

Alternatively for large uncertified machines, using a suitable purge and pressurization system will allow the it to achieve (Ex p) certification after a purge test by a Notified Body.

Expo offer a wide range of certified purge & pressurization and pre-start ventilation systems suitable for all machine sizes and ambient temperatures. Follow the links below to find out more.