Expo’s low temperature motor purge and pressurization systems require compressed air supply at a temperature above -40oC. In cases where the air supply is at a lower temperature, Expo offer in-line heaters to pre-heat the purge air.

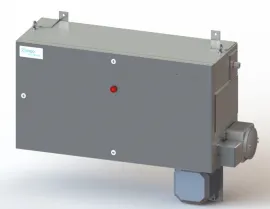

The pre-heaters are self-contained systems designed to elevate and maintain the temperature of high flows of purge system air within a specified temperature range. Air is passed through a coil of tubing, heated using self-limiting trace heating cable. This ensures that over-heating is not possible.

Switching of power to the air heater is thermostatically controlled. A second thermostat gives an alarm signal when the output air temperature drops below a pre-determined value. There is a local alarm indicator as well as volt-free contacts for remote alarm connection.